PIAB

P&E Sales prides ourselves in being the sole distributor in KwaZulu-Natal for Piab South Africa. PIAB Sweden develops and manufactures a complete line of vacuum pumps, vacuum switches, valves, conveyors and suction cups for a variety of automated material handling and factory automation processes.

PRINCIPLE OF PIAB VACUUM PUMPS

PIAB vacuum pumps are compressed air-driven vacuum pumps. The unique construction makes maximum use of the compressed air and therefore consumes less energy. Large vacuum flows and high levels of vacuum are characteristic of the PIAB vacuum pumps. When compressed air passes through the nozzles, air is pulled through with the stream of compressed air. “Suction” is thus created at the opening of each stage, resulting in low pressure, vacuum.

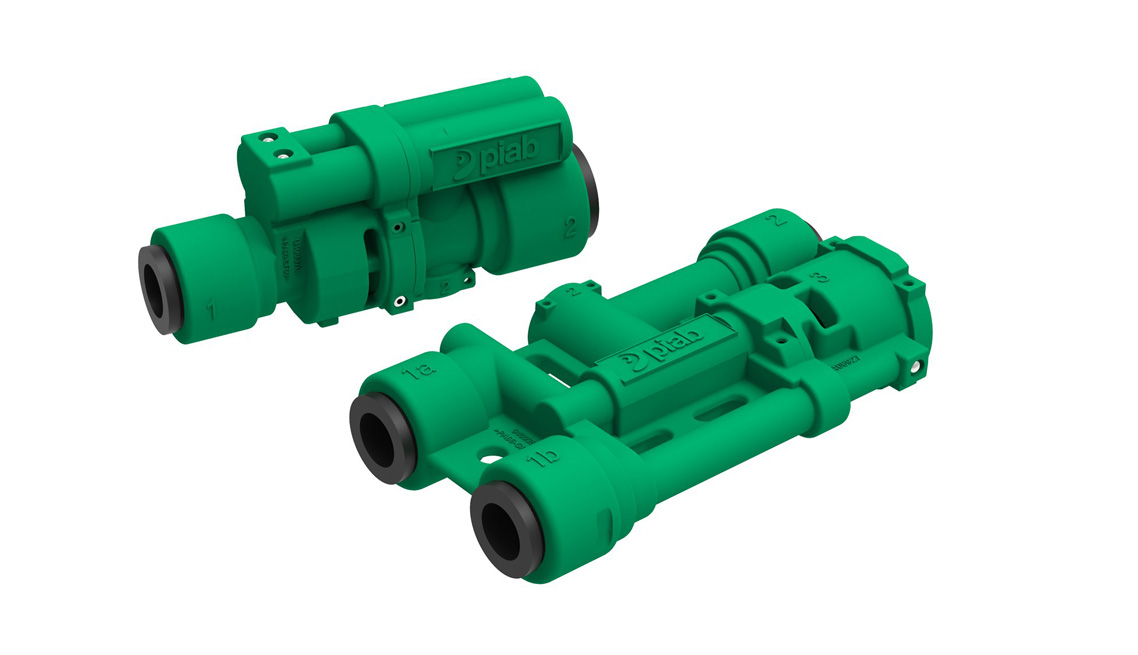

MULTI-STAGE EJECTOR

PIAB vacuum pumps are of the multi-stage ejector type – a technology patented by PIAB in 1973. These vacuum pumps were developed to provide extra vacuum flow in combination with deep maximum vacuum levels while keeping energy consumption at a minimum.

PIAB pumps have no moving parts that vibrate or wear out – important features that contribute heavily to outstanding operational reliability and a pleasant, noise-free working environment.

ADVANTAGES OF PIAB VACUUM PUMPS

- Reliability

- Low energy consumption

- Fast response

- High efficiency

- Require a minimum of service

- Small size and low weight

- Easy to install

- Low noise level

- No heat emission

- No vibrations

- 5-YEAR WARRANTY

PRINCIPLES OF VACUUM CONVEYING

In the filed of vacuum conveying technology we speak of vacuum conveyors being used for “sucking “material. What actually happens is that the air is evacuated from the suction pipe and the pressure of the atmosphere pushes the material into the suction pipeline. It is the atmospheric pressure that indirectly performs the work. The stream of air that is formed upon the pressure equalisation pulls the solid particles into the pipeline.

The material is conveyed from a suction point through a pipeline to a container, where the air and the material are separated. The filter cleans the air before it passes through the vacuum source. A control unit regulates the operating sequence.

ADVANTAGES WITH PIAB VACUUM CONVEYING

- Perfect for powders and granules

- Friendly – Both to your health as well as to the environment

- From 0 to 20 metres in one second

- 15 Tons per hour

- Easy to install any place

- Durable material

- Reliable and easy to maintain

- Operational safety

- Hygiene

PIAB SUCTION CUPS MODELS

Every application requires a particular design of suction cup. The variations described here will cover virtually any need.

U – UNIVERSAL SUCTION CUP

For handling objects with flat or slightly curved surfaces.

B, B-MF – SUCTION CUP WITH SHORT BELLOWS

These cups are suitable for level adjustment. Several short bellows cups in one lifting device can handle objects with height differences and varying shapes. The bellows also provide a slight lifting movement to separate thin items.

BF – SUCTION CUP WITH SHORT BELLOWS AND LARGE LIP

These cups are suitable for uneven surfaces.

BL, BX – SUCTION CUP WITH LONG BELLOWS

The same applications as for short bellows, but can cope with greater differences in levels. This is due to the longer lifting movement. Not suitable for use with deep vacuum levels.

F, F-MF – FLAT SUCTION CUP WITH INTERNAL CLEATS

These cups are suitable for flat objects such as cardboard, sheet metal and porous materials. Cleats prevent objects from being deformed and give extra friction when the lifting force is parallel. The suction cup has good stability and very little movement.

D – DEEP SUCTION CUP

Used for curved and irregular surfaces. These cups can lift even over corners and edges. Not suitable for use on flat surfaces.

SUCTION CUP WITH VALVE

When several cups are connected together in a single system, for example in a lifting device, the system can be adversely affected if a suction cup leaks or misses the work piece. To overcome this, each suction cup can be provided with a valve that opens only when the suction cup is in contact with the object. The advantages are increased safety, less air consumption and faster action.